For the most part the standards were developed when the joints were filled with portland cement mortar and the building interiors were not temperature and humidity controlled.

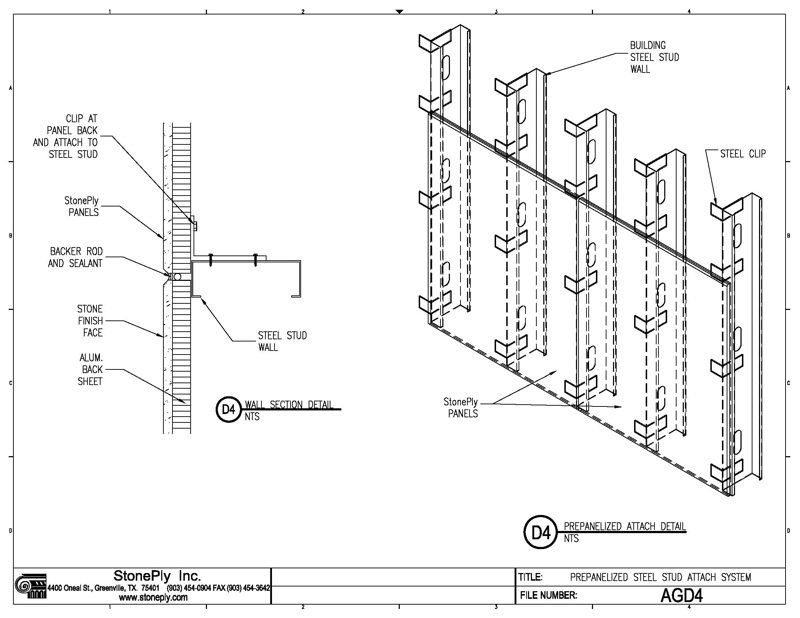

Marble claddingattachment details.

Including limestone granite sandstone and slate.

In a fire solid stone cladding can shatter and break from the intense heat jeopardizing the lives of firefighters and others below.

2016 marble institute of america vertical surfaces general notes page 15 3 have evolved through the years.

Wall covering requirements are covered primarily in chapter 14 of the ibc.

The icc 600 provides more detailed guidance on the building envelope and addresses both the mwfrs and the c c.

Pure white marble is featured in the.

Most panels are fabricated from granite while marble.

Limestone travertine and sandstone are also used to a lesser extent.

Stangle cladding fixation includes design calculation and production of several types of mechanical fixings and accessories used for cladding purposes.

Coordinating tile was created from the same block for adhesive bonding at the lower sidewalk level of the project.

Stainless and galvanized steel are among the various materials used in the fabrication.

Thin stone wall systems used for exterior building envelopes typically consist of stone panels ranging in thickness from 3 4 inches to 2 inches.

Marble and granite mechanical cladding systems.

A common panel thickness is 1 3 16 inch 3 cm.

Detail for c c design is limited.

Cladding attachment systems hardware for installing panels.

We supply a number of aluminum substructure systems that work seamlessly with a variety of exterior panel products.

Our natural stone panels are the perfect choice for exterior interior.

Cladding attachment over thick exterior rigid insulation background current building codes do not provide any prescriptive means to use a secondary support structure for cladding attachment without prescriptive code provisions cladding support systems need to be designed historically done with poor thermal performance and high cost or pre.

Our in house engineering team is is a tremendous resource to our customers as they can assist with design and value options to help the project maintain the architect s vision and an affordable solution.

Our stonelite panels may be produced from almost any natural stone.

Thanks to its lighter weight and aluminum reinforcing stoneply limits the risk posed in a fire.

This high end green slate was custom selected and extracted and required minimal waste to complete all required pieces.

Panel details required bonded corners with radius edges at the soffit.